About Mikadomatsu

- HOME

- About Mikadomatsu

Made with mineral-rich spring water

To sake, water is everything. Depending on whether the water is good or bad, the sake’s flavor fluctuates greatly.

Ogawamachi, where our brewery is located, has been known as a location that is “well-suited for producing sake” from long ago, and it is also famous for having excellent water. The particular water that is used to create “Mikadomatsu” is

spring water filtered by the Chichibu Mountains, which are a series of lime-stone mountains formed by the uplift of the sea due to crustal movements. Rainfall in the Chichibu Moun-tains is filtered through the limestone and passes through

the mountains to become underground water that flows below Ogawamachi over several decades. We pump the water up from 130 meters underground to use in our sake production.

This water has a hardness of 127mg/ℓ and is one of the top-class hard waters in Japan. This hard water is ideal for sake production and is even harder than the “Miyamizu” water found in Nada, Hyogo. A survey by a liquor wholesaler also found that is rich in minerals. However, despite being a hard water, it tastes soft when it is actually consumed, making it a very usual type of water.

This mineral-rich natural water promotes the growth of yeast and creates a unique flavor, sharpness, and roundness. Additionally, by using a low-temperature fermentation tank, it is possible to fer-ment it slowly in a lower temperature range than usual, which imbues Mikadomatsu with its characteristic mellowness and depth.

Rice polishing that removes off-flavoring and highlights the characteristics of the rice

We have long been picky about the type of rice we use to produce our sake. Each type of rice has its own unique characteristics and flavor. In order to produce the taste we desire, we have carefully se-lected varieties such as “Yamadanishiki” from Hyogo, “Bizenomachi” from Okayama, “Sakemusashi” from Saitama, and “Yamasake 4-go” from Yamagata.

We exclusively use brewer’s rice to produce our sake. This type of rice has larger grains than those that are eaten as food. For rice consumed as food, the grains are polished about 7-8% from an unpro-cessed state, however at our brewery, we polish them at a rate of over 30%. The reason that rice is polished is that the surface of the rice has a lot of nutrients such as protein, so when the rice is made into sake, these proteins can produce an off-flavored taste. Polishing the rice is necessary to produce a fragrant and delicious sake. However, if rice is over-polished, the characteristic taste of the rice will disappear. That is why we polish rice to the point where the taste is maximized while still maintaining its unique characteristics.

Thorough management of “fermentation,” the lifeline of sake

“Fermentation tanks” are facilities that manage fermentation, the lifeline of sake brewing. At our brewery, we use top of the line low-temperature fermentation tanks controlled by computers to carefully monitor and keep temperatures in the zone that is desired by our Chief Brewer. These tanks are composed of a double structure and have cold water circulating within the outer part. This mechanism allows for the tem-perature to be thoroughly managed and provides control over “fermentation.”

Depending on the type of sake, fermentation can take up to 50 days from the start of yeast production. As mentioned above, the water used in preparation is mineral-rich spring water that promotes the growth of yeast. Therefore, sake that is brewed in these tanks using slow fermentation in a lower tempera-ture zone, has a fruity aroma and unique mellowness.

Pressing to maintain aroma and umami

At our brewery, we use a large filter-type press. We chose this method to ensure that the unre-fined sake does not come into contact with the air to prevent the escape of the aroma that is associated with high-class sake such as Ginjo sake. This press has aluminum plates and rubber plates arranged alternately, with a tightening structure that uses hydraulic pressure to keep unrefined sake from spilling out. By having the unrefined sake flow through these plates, it can be pressed without exposure to the air. Freshly pressed raw sake and Ginjo sake are immediately stored in the refrigerator, and other types of sake are sent to stor-age to wait for aging. For Daiginjo, we use the traditional method of pressing using only the weight of the unrefined sake.

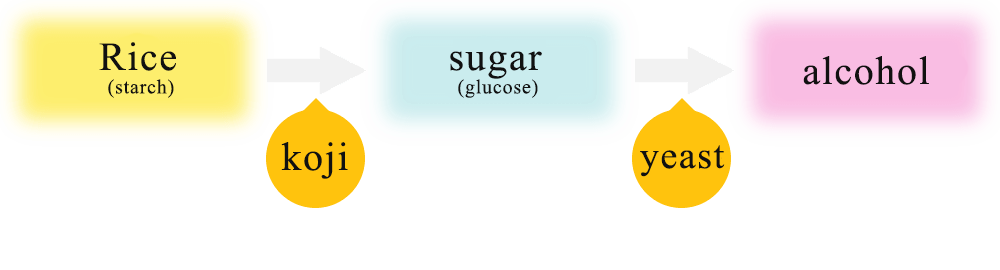

The two bacteria which create sake

There are two important bacteria used in the creation of sake. These are “koji” and “yeast.” “Koji” is a type of mold that changes rice starch into sugar. “Yeast” eats the sugar produced by the koji and produces alcohol and umami

components.

*When yeast produces alcohol, it also produces carbon dioxide. This is why new sake contains carbonic acid.

There are different types of koji and yeast bacteria, so just like with our rice, we use different varieties depending on the type of flavor and quality we wish to achieve.

Controlling the action of the “koji” and “yeast” is the key to making delicious sake, so we pay close attention when working with them.

7-2 Shimofurutera, Ogawamachi, Hiki District, 355-0326, Saitama

TEL 0493-72-1234(Weekdays 9:00 - 17:30)